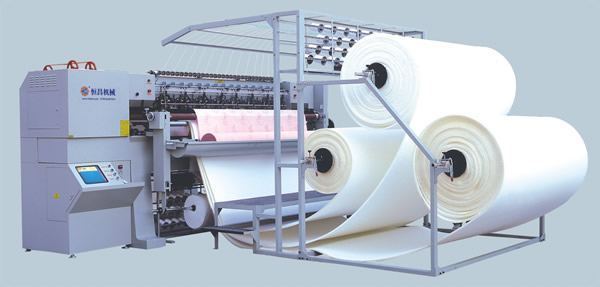

SPECIAL FUNCTION:

·Function of automatic stop on breaking of thread and needle raising.

·Bottom thread cutting and fabric rolling are the fastest in the world with production rate of 20% to 50% higher than any other quilting machines in the nation.

·Bottom stitch uses common mixed cotton thread for all patterns.

·Very little deformation when quilt on between thick and thin fabric.

·Uses high speed aero dynamic bottom thread cutting machine architecture, and therefore, can produce an uniform and threadless edge.

·Both X and Y axes are driven by high power Panasonic servo motors that are capable of quilting fabric materials at 50mm in thickness.

·Extended horizontal movement (moving distance of 450mm), can produce super large patterns.

·Spacious look with the single unit design.

·Nation's first built multi independent quilting machine.

·(This machine is also capable of quilting single independent, all round 360 degree and 180 degree patterns.)

Technical Specification:

| Size (length*width*height) | 4800 x 1220 x 2000(mm) |

| Weight | 3500kg |

| Quilt width | 2450mm |

| RPM | 750-950 RPM |

| Production speed | 65-180 m/h |

| Needle type | 160/23 180/24 |

| Needle arrangement | (50.8, 76.2, 127) (76.2, 76.2, 152.4) |

| Max. horizontal movement | 450mm |

| Needle space | 25.4mm |

| Voltage | 380V 50Hz 220V 60Hz |

| Max. Stitch size | 2-7 mm |

| Power | 4.5 KW |

| Quilting thickness | ≤50mm |

Feature Icon:

| Simple Menu, Easy To Operate | Cam Type And Eight-working Station Structure |

Applications:

Mattress panel, pads, bedspreads, bedding, comforters and so on.